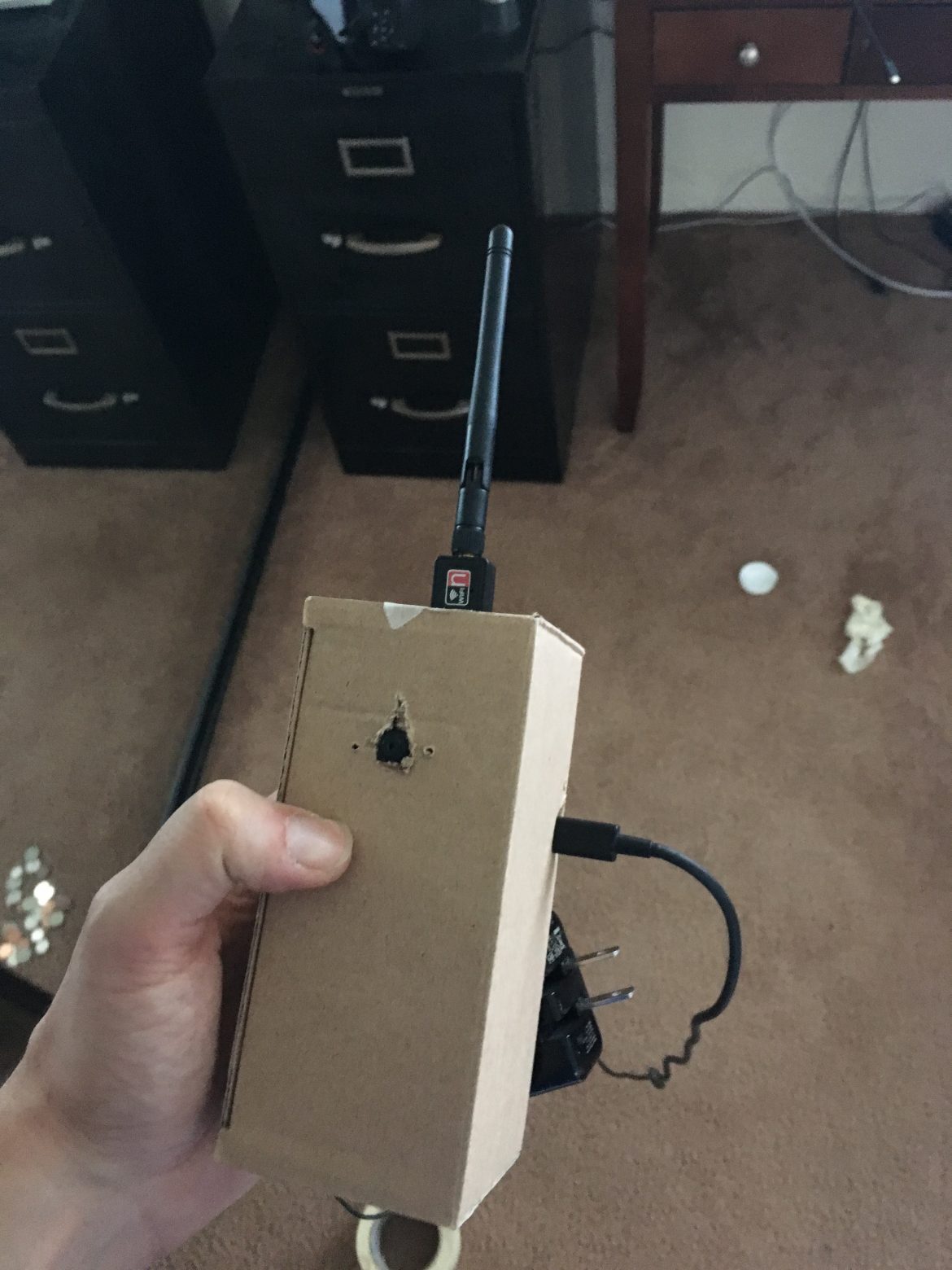

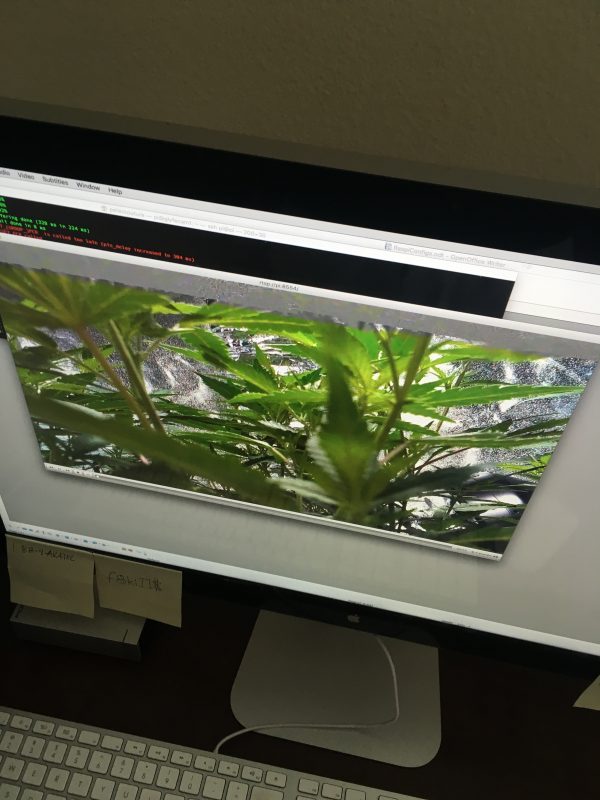

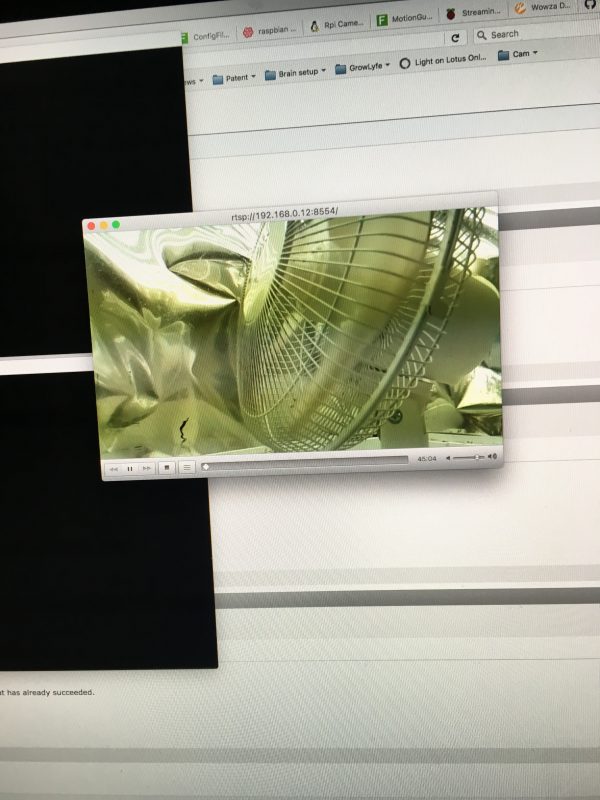

Around this time the 4×4 tent I was vegging in had reached capacity and it was time to upgrade. I decided to purchase a second 600W light and remove the tent. This was a large upgrade as it dedicated the entire room to the cultivation.

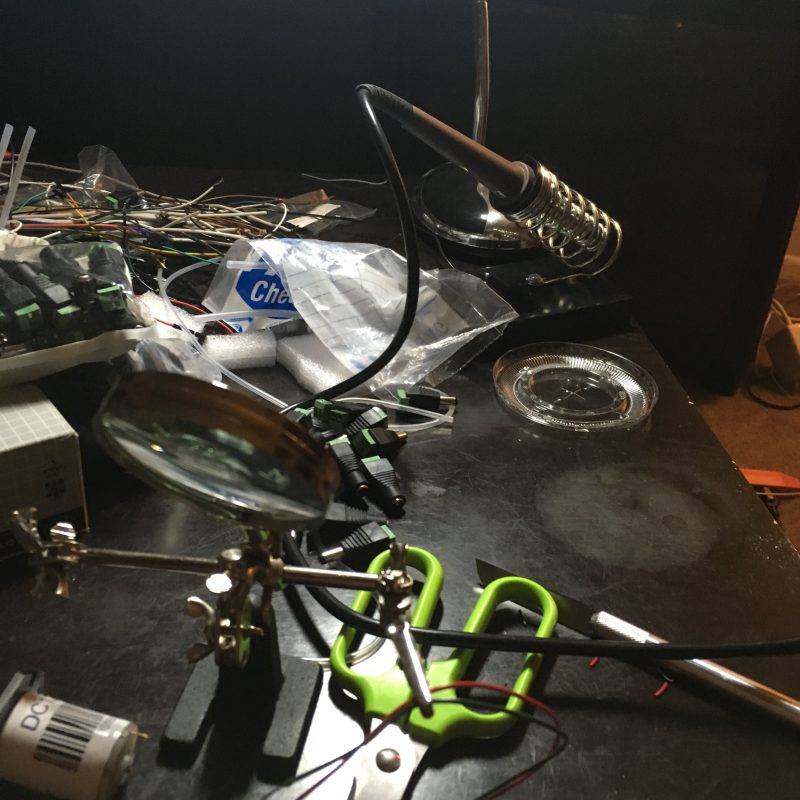

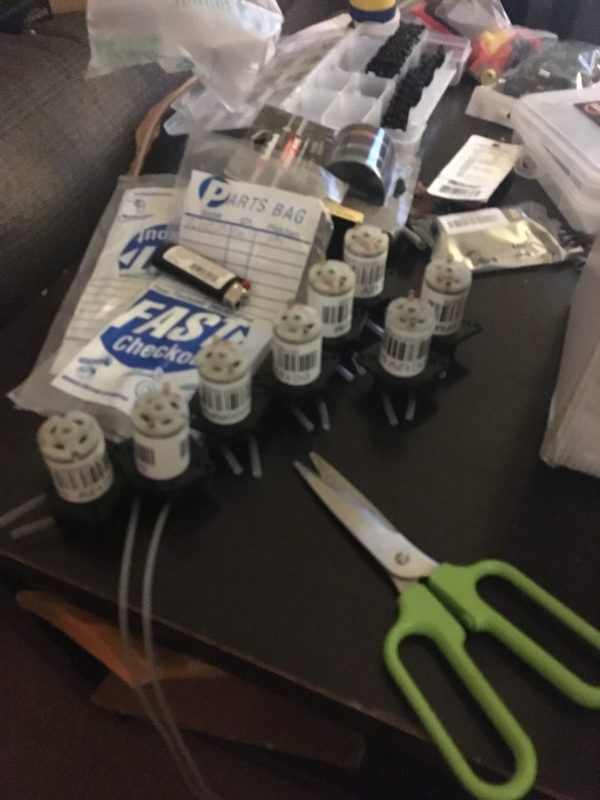

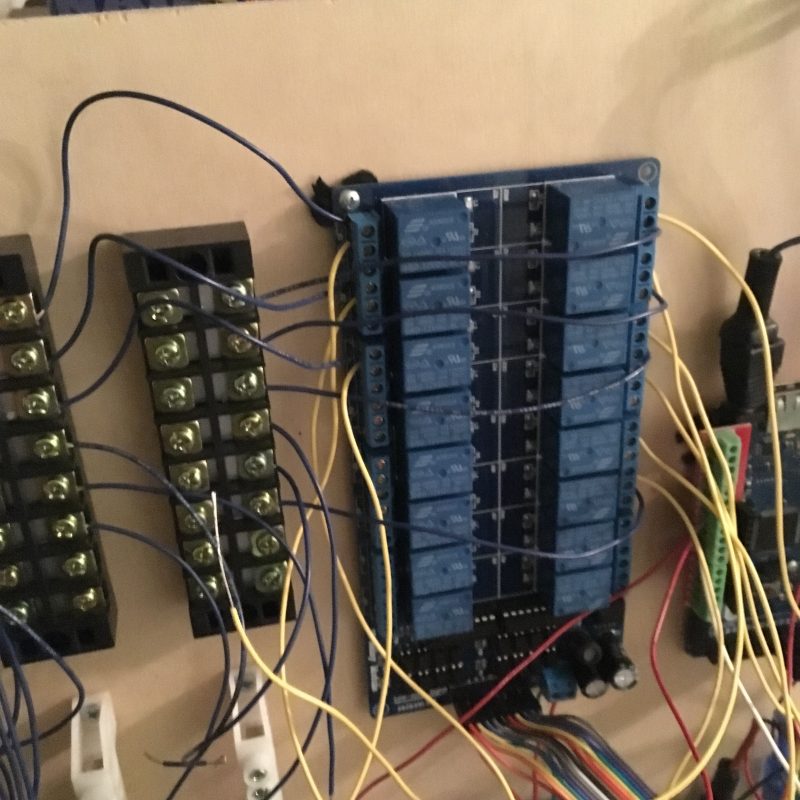

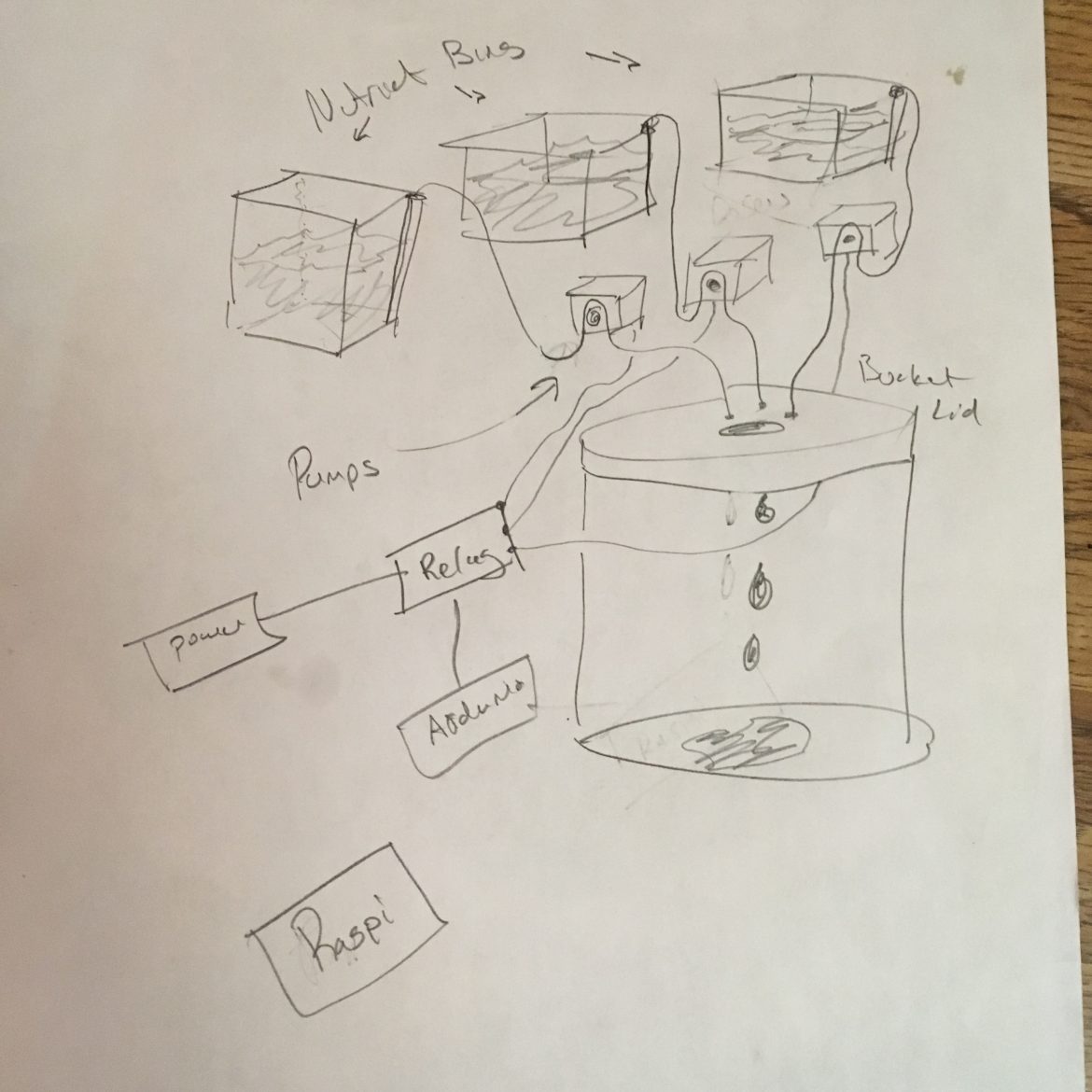

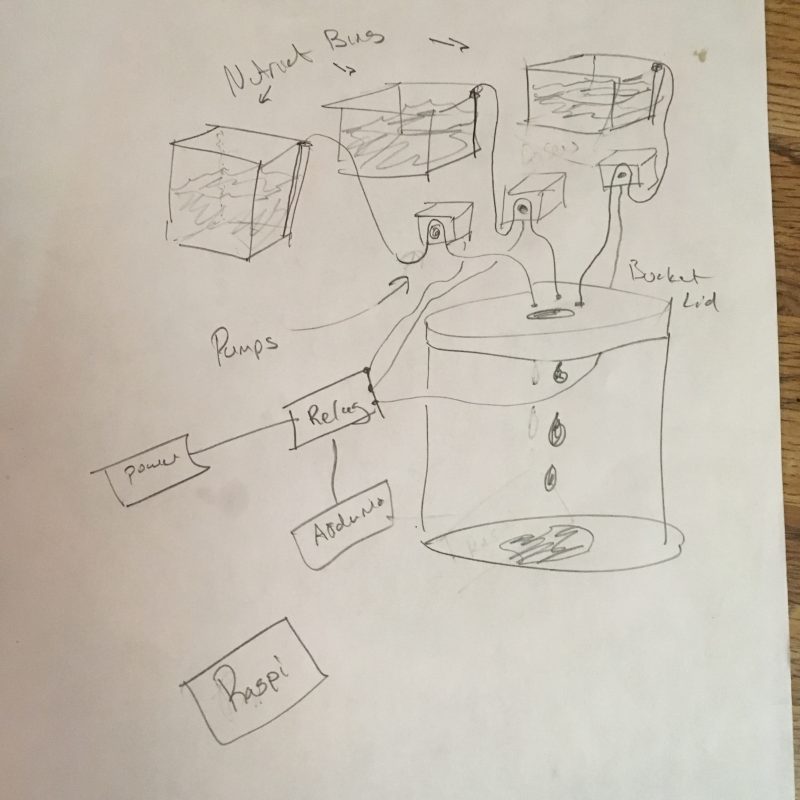

Now was the time to move on and create the dosers for the nutrient solution. These were prototype only and ended up needing a bit of software control to function. In the end next time I’ll likely try a different way to dose the nutes.

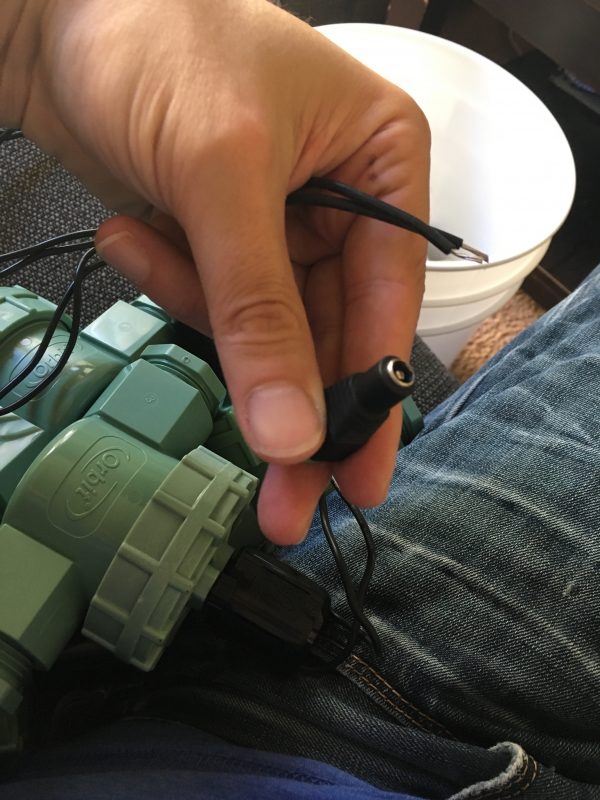

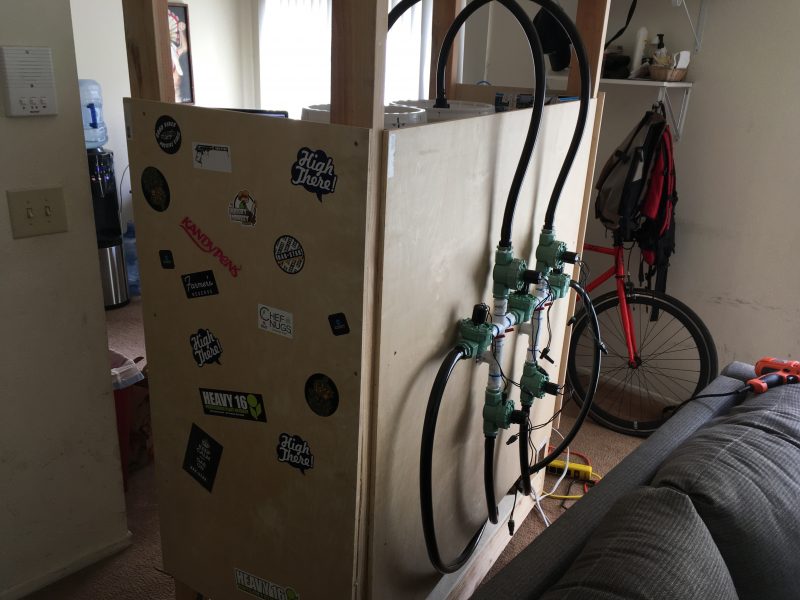

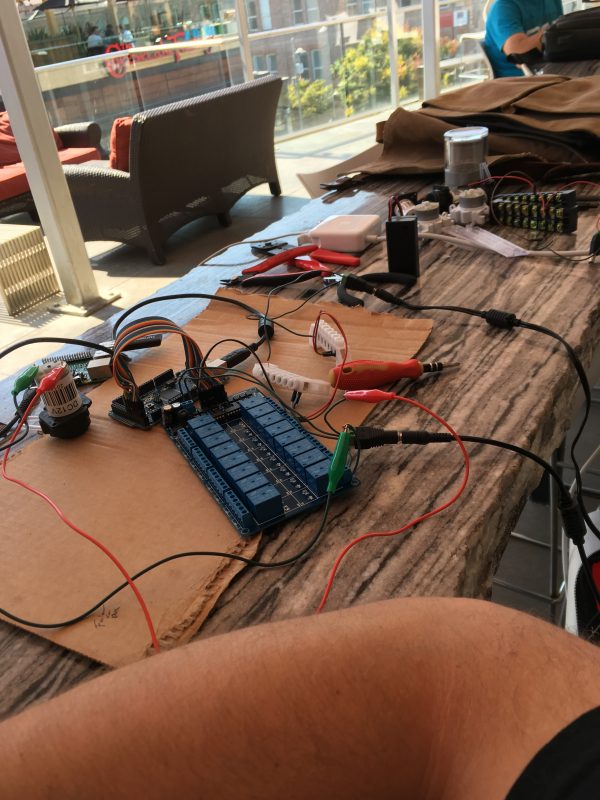

Now the electrical and framing for the case is complete we need to add the plumbing. This ended up being a bad system design as the valves I used require main line water pressure to open and the pumps I used in the system couldn’t reach it. In the end I cut the values out and just directly fed everything.

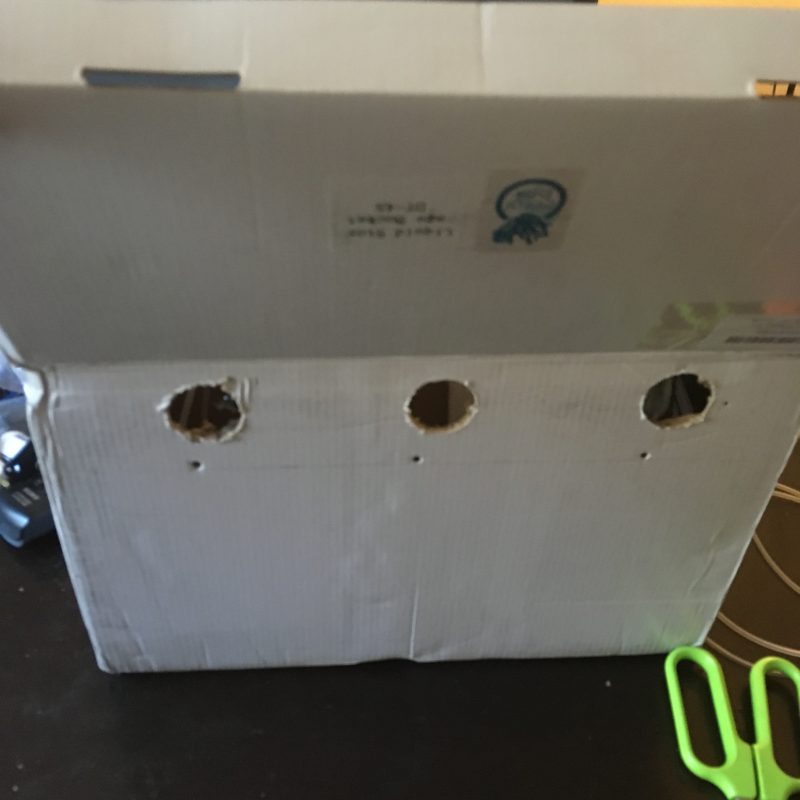

Continuing on with the nutrient mixing system it was time to put the cabinet together that would house the prototype. Lumber was purchased and cut at the local mill and the assembly began. I was able to mount the mixing buckets and overflow containers into the frame at the end.

Work began on the next version of the nutrient mixing machine. Chemical grade dosing containers were purchased and the system work began.

Home made nutrient mixer

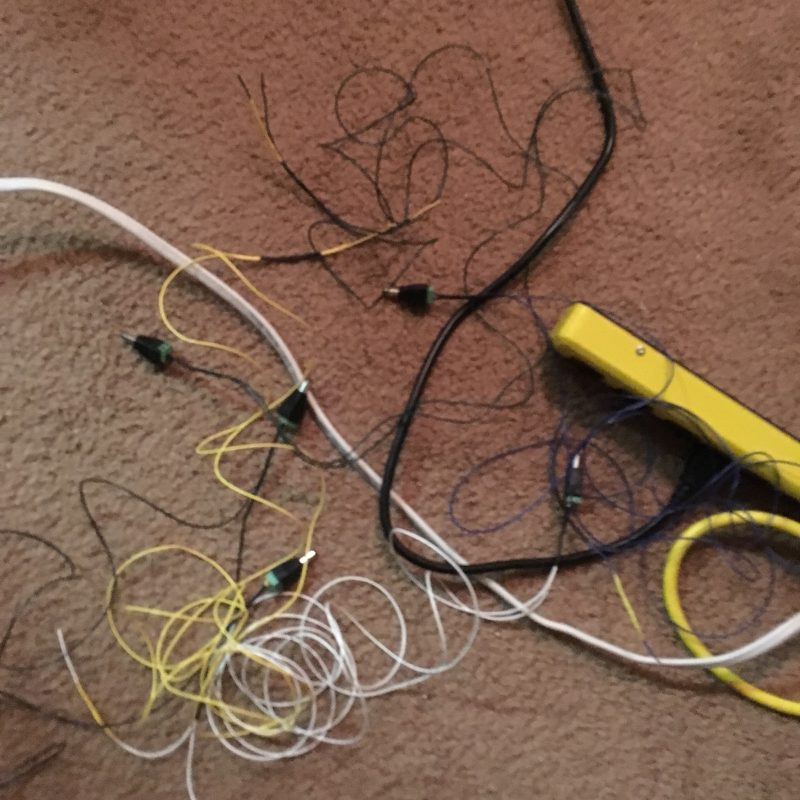

This was the beginning of working to automate the feeding process. The steps I had been learning thus far were so manual. I knew there had to be an easier way. This was the first device built based on a growers recommendation. It’s a basic mixer setup that moves the fluids around the bucket allowing for even mixing.

Small pump to move things around

Later I would realize this design was not practical for small scale, hand feeding style operations. Solution doesn’t need to be constantly mixed, and constantly running the pump raised the temperature of the solution to unsafe levels. This was the beginning of researching long term solutions to the problem of automated feeding.

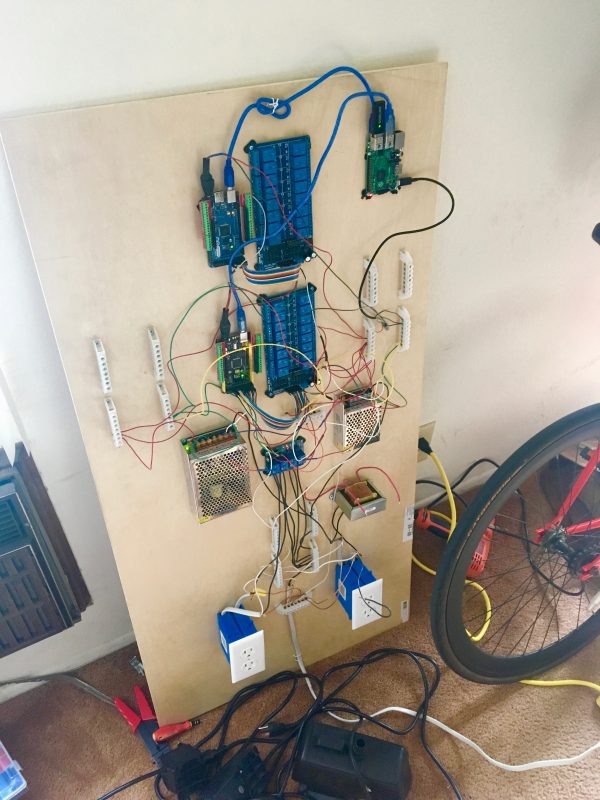

The enclosed bucket

Pumping the solution around