The beginnings of learning larger scale developed. Seedlings were sown for the first time and a row of cuttings were taking from the 4th generation Lemon Haze plants. It was a skill to learn not something viable for a craft level grower. In future keeping it small and simple was preferred.

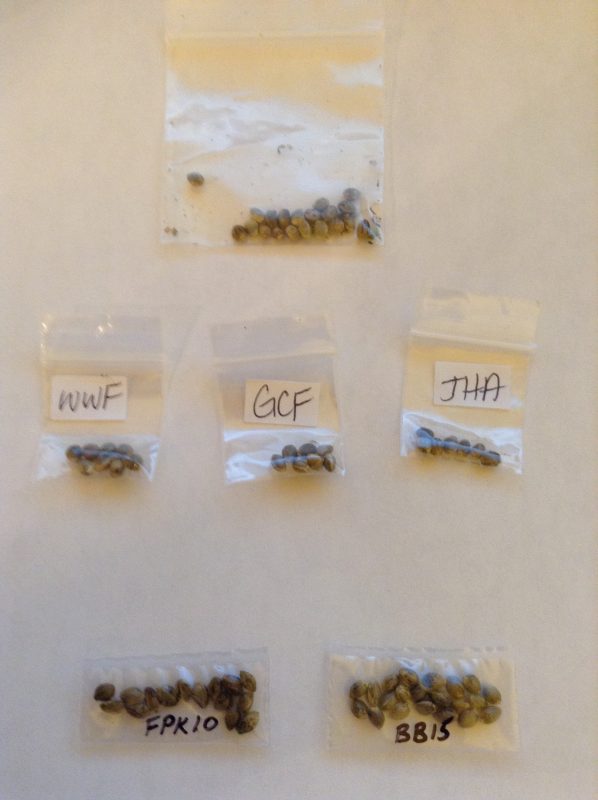

The resulting clone bin with seed and clones. Popagating seed in rockwool cubes is not recommended as I found the seed has difficulty uprighting itself.

A few days later. This is stunted growth for seedlings. I found they grow faster in an open air pot then a dome.